- For a slot or hole 1' diameter then the minimum distance 'D' = 2.5T + R (see fig. 'C') Form height to thickness ratio – To determine the minimum form height for sheet metal use the following formula: D = 2.5T + R (see below) The height can be less but it required secondary operations and is far more costly.

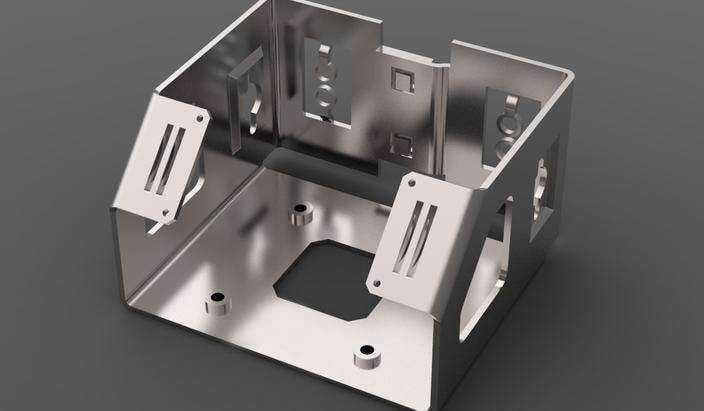

- Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part.

SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. We can use these features to create sheet metal designs with several different methods. We will focus on the flange method, where a sheet metal part is created in the formed state using specialized sheet metal features.

To begin we first want to turn on the Sheet Metal tab on the CommandManager. To do this we simply need to right-click any tab on the CommandManager and select Sheet Metal from the drop down menu.

Sheet Metal Tab And Slot Design Guide Free

Next, we will activate the Sheet Metal tab of the Command Manager and click Base Flange/Tab tool, which should be the first tool on the right not grayed out when beginning a part.

Sheet Metal Tab And Slot Design Guidelines

To begin this part, just like any other, we need to select a plane and create a sketch. In this case, we will create a simple, open sketch to begin our sheet metal part.

There are specific sheet metal features you can use to create sheet metal bodies quickly. However, in some circumstances when the design requires certain types of geometry, you can use non-sheet metal feature tools, then insert bends or convert the part to sheet metal. Because sheet metal products have a history of being designed by the guy who actually does the work on the floor, sheet metal products (think HVAC ducting, as well as the lockers in your gym) tend to be excellent examples of design for assembly, especially when looking at self-locating parts, which reduce assembly errors.

Once the sketch is confirmed a preview of the sheet metal part appears in the graphics area and the Base Flange property manager comes up to the left. Starting from the top of the property manager, the first section is Direction 1. Similar to a basic extrude feature, an end condition needs to be selected and a dimension also needs to be determined.

The next section of the property manager is Sheet Metal Gauges, the only option in this section is a checkbox to us a gauge table. If the checkbox is selected a gauge table can be selected from the drop-down menu to control the thickness of the sheet metal part. A gauge table is a spreadsheet that stores values for the gauge thickness as well as the bend radius. The default location for these tables is located at C:Program FilesSOLIDWORKS CorpSOLIDWORKSlangenglishSheet Metal Gauge Tables

If no gauge table is used the thickness of the material and bend radius can be entered in the Sheet Metal Parameters. Here we can also choose to reverse the direction which determines on which side of the sketch material is applied.

In the Bend Allowance section, we can select how SOLIDWORKS determines where the neutral axis is the flat pattern calculation. By choosing K-Factor, Bend Allowance, or Bend Deduction from the pull-down menu, a specific value can be entered. By choosing Bend Table or Bend Calculation, an Excel document can be used. (For more info on this: https://www.hawkridgesys.com/blog/sheet-metal-understanding-k-factor)

The last option in the property manager allows you to choose a relief type that will automatically be added when a bend requires it.

Once you have made your choices for each of these options and you hit the green check you are left with a sheet metal part. You will now access to all of the sheet metal tools on the Sheet Metal tab of the CommandManager. You’re on your way and can now start adding any other sheet metal features required.

For more information on SOLIDWORKS 3D CAD, visit Hawk Ridge Systems today!